Kilns

I got two kilns: one smaller made out of lightweight isolating bricks and a bigger twochambered Noborigama-type kiln

I got two kilns: one smaller made out of lightweight isolating bricks and a bigger twochambered Noborigama-type kiln

When firing highfired stoneware you have to reach temperatures up to 1300 degrees Celsius. To achieve this you have to build your kiln so that it draws downvards in order to make it possible for the heat to accumulate in the main chamber before escaping from the chimney. The fireboxes are of Bourry-box type. This means that at higher temperatures they start to function as carburetors producing unburnt gases that will ignite only in the main chamber of the kiln. As a result the temperature in the main chamber will be higher than in the firebox a fact that makes the firing quite efficient.

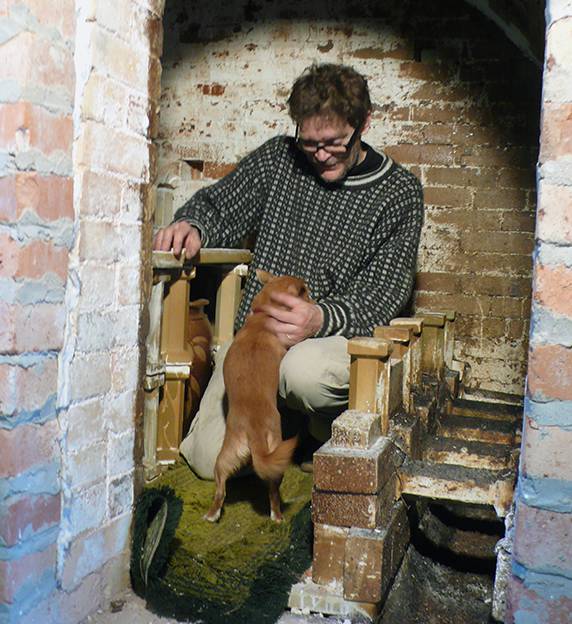

Loading the kilns

I don't bisquefire my pots. This asks for more carefullness while handling and glazing the pieces, but on the other hand it saves me a lot of work and energy. When firing with wood simplicity often leads to more beauty: I often leave the outer side of my pots unglazed giving opportunity to the flames and flyash to do the rest.

When loading the kiln I use soft wads between the shelves and the props thus stabilizing the high and sometimes wery heavy stacks. It is also a good idea to exaggerate the stability of the lower shelves, you'll never regret it afterwards. During wintertime keeping the claywads from freezing can be a problem, but you have anyhow to count for more time for everything (except skiing) during winter. Before starting to load the kiln I have an approximate idea of where to place each pot but the placing of a single pot depends also of the size and glazes of the surrounding ware and the interest the potter takes in this particular pot, so loading is always a matter of compromize and a constant challenge to the potter.

Firing

I always preheat my kilns the night before with one or two gasburners. In a big twochambered kiln there is a risk of condensation in the second chamber if this is not thorougly warmed before starting the proper firing. This is especially important in cold conditions. I havent noticed any significant difference in the duration of winterfirings even though the temperature can be tens of degrees colder than in the summer. Maybe this is due to cold air being denser and thus containing more oxygen wich makes the combustion more efficient. This would compensate for the difference in temperature.

The only criteria I have for the firingwood I buy is that it has to be cheap and dry. I most often purchase about ten cubic meters of spruce from a stack by the road, cut the logs in pieces of one meter and split them with a tractordriven splitting device. The logs are then left to dry ower the summer. Sprucewood dries easily and has a long flame, but it also burns down faster than hardwood.

When woodfiring, the potter tends to be full of energy and impatience in the beginning of the firing, when one has to take things easy and slowly and at the end of the firing, when instead everything is at stake and one needs to be active and thinking clear, our potter is usually mentally and physically exhausted. A good rule is in any case never to start a firing when already tired and to add a couple of extra hours of firing before finishing. I use also to keep the temperature at around 1010 degrees Celsius for a couple of hours in order to give time for eventual carbon to burn off the thicker pieces thus avoiding bloating.

The second chamber is used for saltglazing. The chamber has its own door for stoking. While switching from the first to the second chamber I continue occasionally to throw some logs into the main firebox in order not to let the first chamber cool down too fast. I use about 5 Kgs of course salt for one saltglazing. The smaller kiln takes about 14 hours to fire, this is too long for a kiln of that size and I plan to enlarge the firebox hoping this would help. The bigger kiln fires in about 36 hours. It cools down in around six days.